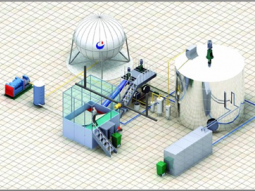

The plant is located in the southeast of the Province of Buenos Aires, approximately 470 kilometers from the Argentine Federal Capital, 50 kilometers from Puerto Quequén for bulk cargo and containers, and 380 kilometers from the Port of Bahía Blanca. Located in the vicinity of the city of Lobería, on an eight hectare field, it has offices, a vegetable oil production plant, expeller, edible oil bottling and biodiesel production.

Products:

The installed equipment allows for the production of three types of oil, expeller, palletized and Biodiesel: First cold-pressed extra virgin sunflower oil. This oil, with very low acidity and preserving all the intact properties of the original seed, can be bottled in the factory and sent for distribution to supermarkets in Argentina and for export in ½ liter and 1 liter glass bottles. Sunflower oil obtained by second hot pressing, unrefined. This oil does not undergo any chemical process or solvent extraction in our plant, and is suitable to be sold in the domestic or export market, destined to industrial establishments. Even for the production of Biodiesel in our own plant. Crude soybean oil by extrusion and pressing method. Sunflower and soybean expeller. Biodiesel.

Markets:

Unrefined vegetable oil constitutes the main item of Argentina's exports. The company provides a higher added value by producing cold-pressed extra virgin sunflower oil, without chemical components. The soybean oil is destined for chemical industries and biodiesel production. The equipment also delivers both sunflower and soybean expeller for use as a protein supplement for animal feed, with a high percentage of protein and a residual fat content of 4%, which allows meeting the local demand for animal feed. Biodiesel is destined both to supply the regional and national market.

Facilities and equipment:

The plant is equipped with the following equipment:

-NEUMATIC CALCULATOR to obtain grain samples upon entering the plant ELECTRONIC SCALE with a capacity of 80,000 kg.

-HYDRAULIC TIPPING PLATFORM for trucks with a capacity of 45,000 kg.

-GRAIN DRYER with a drying capacity of sunflower from 15% to 7%, temperature 60/65 °C-22 Tn/hour. Soybean from 13% to 10.5%. Includes gas burner, high temperature cut-off (advance notice) digital thermometer with PT-100.

-GRAIN CLEANING MACHINE WITH SUPERPUMPED SCREENS with a capacity of 180 tons/hour.

-GRAIN STORAGE PLANT with a capacity of 4,000 tons with four (4) metallic silos, capacity 1,020 t/wheat each one, central waterwheel of 80 tons/hour, pre-cleaning machine, grain receiving grid and aerial pre-grinding silos.

-OIL PRODUCTION PLANT with capacity to process 60 tons/day of seed, consisting of a dehuller/screen with a capacity of 100 tons/day, a breaker mill, two stoves, two extruders, two presses, two presses, two borers, two buffer tanks, two filter presses and an expeller cooler.

-OIL STORAGE TANK. The plant has four tanks of 50,000 liters each for the storage of cold-pressed extra virgin oil and two tanks of 250,000 liters each for the storage of crude oil.

-LABORATORY: An adequate laboratory was installed to carry out all the corresponding analyses, both of raw materials and of the final products.

-PACKAGING PLANT. A fractioning, bottling and labeling plant was installed with a capacity of 2,000 bottles/hour for oil bottling. Automatic filler with two simultaneous filling nozzles.

-PALLETIZING PLANT. It has expeller palletizing plant.

Building:

A building was constructed in which were arranged: oil extraction plant of 500 m²; warehouse for storage of expeler of 500 m²; fractioning, packaging and labeling plant of 300 m²; and, warehouse for packaging material of 300 m². BUILDING for office, restrooms and personnel dressing rooms.

-ELECTRIC POWER FACILITY with 13.2 kVA line extension and transformer substation.

-BOILER for steam generation, with double burner, both gas and sunflower husk.

-Electrical, sanitary and gas installations, electronic controls and automation, fire prevention system, etc.

-BIODIESEL PRODUCTION PLANT

- CHARACTERISTICS OF THE L60-BIO-1 PLANT. The plant is designed by CONICET researchers for biodiesel production.